MCBs: the what, why and how

Most of you may be familiar with miniature circuit breakers (MCBs), but do you know how they actually work?

MCBs have been around since 1923 (patented in 1924). Today, MCBs are installed in homes, offices and other buildings, protecting electrical wires from overloads and short circuits. The fundamental principle, however, is based on the first “electromagnetic circuit breaker” patented by Hugo Stotz in 1924. Since then MCBs have been further advanced, continuing the pioneering spirit of Stotz.

Looking on the inside of a miniature circuit breaker can help understand how they actually work. For overload protection, the temperature of a bimetal, through which the current passes (yellow area), is decisive. If the nominal current — the current the circuit breaker is designed for — rises slightly, the bimetal heats up to a greater extent and, after a certain period of time, this causes the switching mechanism to trip.

Short-circuit protection is located in the electromagnetic coil (green area). In the event of a short circuit, the current rises very sharply and the coil creates a magnetic field that both trips the switching mechanism and opens the contacts via a quick release mechanism. The additional quick release for opening the contacts in the event of a short circuit helps to keep the energy of the short circuit to a minimum, which in turn keeps the ‘stress’ the wires are subjected to as low as possible.

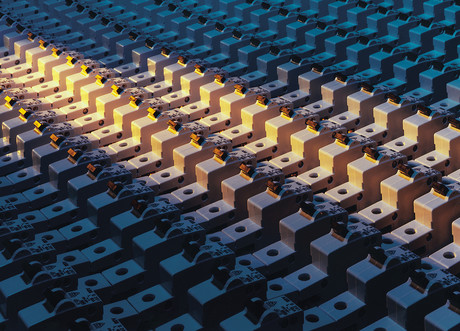

In both cases, ie, short circuit or overload, the shutdown process results in an electric arc between the contacts of the MCB. This electric arc is actually counterproductive when trying to ensure a separation of the two circuits. In order to extinguish the arc, which has a temperature of more than several thousand degrees Celsius, it must be directed away from the contacts, over the arc runners and past the pre-chamber plates to the arc chamber (blue area). In the arc chamber, the formerly powerful electric arc is split into several smaller arcs until the driving voltage is no longer sufficient and they are extinguished.

Release mechanisms

A miniature circuit breaker has various tripping mechanisms — (A) it can be switched on/off manually, (B) it can be tripped thermally and (C) it can be tripped electromagnetically. The electromagnetic and thermal tripping for short-circuit and overload protection work separately from one another. In addition, certain fitments can affect the tripping mechanism (eg, shunt release).

The manual switch is obvious and warrants no further explanation.

The thermal tripping mechanism functions with the help of a bimetal strip (see figure, explanation 2). As the name suggests the strip is made of two different bonded metals with different expansion coefficients, such as brass and steel. When the circuit is overloaded, the bimetal strip gets hot and one metal in the strip expands more than the other and it bends, triggering the switching mechanism (see figure, explanation 7), causing the MCB to trip. The ‘trip’ function is triggered by means of a spring-loaded accumulator. Here, the bimetal can be heated directly or indirectly and, due to its expansion coefficient, its action is time delayed. The key factor for tripping the switch mechanism of a circuit breaker is the heating — ie, the current + time. Thermal tripping is the most common type of trip in apartment buildings.

Electromagnetic tripping occurs under different circumstances, for example, when a current runs from an external conductor through the metallic housing of a lamp. The low-resistance connection to the green-yellow PE conductor to the housing, and thus to ‘earth’, causes an electromagnetic trip and the MCB provides protection against indirect contact in accordance with VDE 0100-410.

So how does it work? Electromagnetic tripping occurs by means of what we call an impact anchor (see figure, explanations 8 and 9). The action is accelerated powerfully and quickly by magnetic forces in the direction of the movable switch contact, thus isolating the contact as quickly as possible. Further tripping is triggered by a mechanical construction that acts on the spring-loaded accumulator and resets the shift lever (see figure, explanations 6, 10 and 11).

Due to ABB’s ‘trip-free’ mechanism, both the electromagnetic and thermal tripping mechanisms are active when the switch lever is blocked in the on position. This guarantees effective protection, and prevents switching on when a fault is present. ABB’s MCBs are produced at the Heidelberg site in a cutting-edge manufacturing plant, which has recently been awarded the Industry 4.0 award.

Benefits

Unlike fuses, which can only be tested by random sample and in doing so renders the fuse useless, every MCB undergoes a thorough functional test.

During the test both the thermal and magnetic trips and the mechanical functions are checked. Herbert Franken, author of the book Niederspannungs-Leistungsschalter (Low-Voltage Circuit Breakers), identified the following advantages of miniature circuit breakers when compared with fuses:

- Switching off covers all poles.

- During low over-currents and moderate short-circuit currents, turn-off times are shorter than for fuses.

- Overload and short-circuit characteristics are correctly assigned by the manufacturer, and tripping accuracy is high.

- Operation is safe even during the most severe overload conditions.

- Once a failure has been rectified, the MCB is immediately in a ready-to-use state without any parts needing to be replaced.

- Switch positions can easily be made visible.

- Remote tripping is possible.

- MCBs are also disconnectors, which fuses, if fusible inserts are used, are not.

Can cathodic protection design support ESG outcomes?

Omniflex's David Celine explains how CP system design can support environmental, social and...

Designing a robust cable for aquaculture

To ensure the health of farmed marine animals, the components of an aquaculture system must work...

Protecting your enclosures from environmental hazards

Ingress Protection (IP) ratings provide valuable information about the protection level of an...